Value Chain

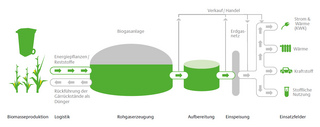

Biogas feed-in offers added value at many levels: biomass production, logistics, biogas production, biogas processing, feed-in, and sales and trading. At each of the value creation levels mentioned, there is potential for optimization of a technical and economic nature. Industry-specific know-how is needed to exploit this potential.

-

Since biogas can basically be produced from all organic compounds (biomass), the biomass used is correspondingly diverse. On the one hand, biomass is produced by agricultural workers by growing suitable plants. On the other hand, biogenic residues and waste materials are used. The biomass for use in biogas plants is also referred to as substrate. When using residues as a substrate, any available organic material can be used. Of particular importance here are manure, organic waste and sewage sludge, as these are available cheaply in large quantities as waste products.

Energy plants

Energy plants are plants that are grown specifically to generate energy. Fast-growing plants with a high photosynthesis rate, taking local environmental conditions into account, are suitable as energy plants. In Central Europe, corn, rapeseed and rye are mainly used. In some tropical countries, the cultivation of sugar cane as an energy crop is widespread.

Maize is particularly suitable for use in biogas plants due to its high land efficiency and synergies in the production of animal feed, but grain (e.g. rye) and/or grass clippings can also be used. The choice of plants used varies from region to region and should be adapted to local conditions. One thing to be careful about is that the change in land use does not lead to negative ecological consequences. -

When it comes to biomass logistics, it is important to avoid long delivery routes for the substrate to the biogas plant for energy and economic reasons. Since the biomass is only harvested during short periods of the year, this requires a well-planned logistics chain.

In principle, a distinction is made between concepts with decentralized and centralized storage:

Decentralized storage is usually used when there is already sufficient capacity in the vicinity of the biogas plant to store the biomass required for the year. The biomass is then delivered to the plant continuously (just in time). This ensures high utilization of the means of transport, since the resulting dry fermentation substrate can be transported away as return freight. However, the personnel costs are relatively high, since deliveries have to be made several times a week.

The second concept is the central storage of the biomass at the biogas plant. The main advantages here are the constant silage quality and the lower logistics costs. However, higher investment costs are incurred, since storage capacities have to be created. However, by reducing silage losses by around ten percent, costs of two euros per tonne of silage can be reduced for central storage compared to decentralised storage. The choice of transport method depends on the distance of the cultivated area from the biogas plant. For short distances, transport by tractor is cheaper, as there is no need to load the material after chopping. For longer distances, transferring to trucks can be cheaper.

-

Raw biogas

Raw biogas is produced by the fermentation of substrates of biological origin. This takes place in so-called fermenters. These contain microorganisms that produce biogas as a metabolic product. The processes that take place during fermentation are very complex and are still not fully known. Various research projects are dealing with this topic. The measurement and control technology used is crucial for optimizing the process.Raw biogas consists of 45 to 70 percent methane (CH4). The second largest component, at around 25 to 50 percent, is carbon dioxide (CO2). Small amounts of hydrogen sulfide (H2S), ammonia (NH3) and water vapor (H2O) are also produced. Depending on the class, fossil natural gas consists of 85 to 98 percent methane. In order to ensure a constant quality of the gas available in the gas network, the methane content of the raw biogas needs to be increased.

Methane yields

The combustible and therefore relevant part of the biogas is methane. As a result, the percentage of methane contained in the biogas should be as high as possible. The methane yields differ mainly due to the substrate used. By optimizing the system technology for the respective substrate and by using modern measurement and control technology, the methane yields can be increased even further -

From raw biogas to biomethane

The raw biogas can be processed to natural gas quality using various processes. The most important step is increasing the calorific value by separating the CO2 contained in the raw biogas. Depending on the process, processes for drying the gas and cleaning sulfur compounds and other trace substances are also necessary. The order of the individual processes depends on the processing process selected. In addition, feeding into the natural gas network can make an additional calorific value adjustment (e.g. by adding liquid gas/LPG) and odorizing the biomethane necessary. Due to the extensive equipment required for biogas processing and feeding, the specific investment costs are usually higher than those for on-site power generation plants. For smaller biogas plants, combining the raw biogas from various fermentation plants into a common biogas processing and feeding plant can therefore be an option.Desulfurization

Depending on the substrate composition, sulfur compounds can be present in raw biogas in sometimes high concentrations. Sulfur often occurs as hydrogen sulfide (H2S). Other sulfur compounds are included in the total sulfur parameter. These trace substances have a corrosive effect and must therefore be removed from the biogas. Otherwise they endanger plant components and gas consumption devices. The available processes are divided into coarse and fine desulfurization according to the sulfur concentration in the clean gas.Gas drying

Adsorptive processes and condensation processes are mainly used to dry biogas.Condensation process

If biogas is cooled, the water vapor it contains condenses. The water can be removed from the process and discharged. This process is mainly used when biogas is used in CHP plants. The moisture content achieved with this process is usually not sufficient to meet the requirements of DVGW G260 and G262. Therefore, the condensation process usually has to be supplemented by another drying process.adsorptive gas drying process

The adsorptive drying process is based on water vapor attaching itself to certain substances (e.g. molecular sieves, silica gels or aluminum oxides). These substances are introduced into the process in a fixed bed adsorber and remove the water from the biogas flowing around them. The drying agent must be regenerated after adsorption. If the biogas plant is to feed continuously into the grid, at least two separate fixed bed adsorbers must be used. Then one adsorber can be loaded at a time while the other is being regenerated.CO2 separation

The separation of carbon dioxide from the raw biogas is necessary to increase the calorific value of the gas. Various processes are used, with the following processes being particularly popular on the European market: -

Feeding biomethane into the grid enables the use of biogas far away from the production site. After processing, the feed-in takes place primarily via a compressor, which raises the pressure level of the biomethane to that of the connected compressed gas pipeline. The prerequisite for feeding in is that the quality of the biogas to be fed in complies with the provisions of the local gas class and that the deviations do not exceed the limits permitted to comply with the quality standards.

When feeding in biomethane, a distinction is made between replacement gas and additional gas. The difference lies in the quality of the gases. Replacement gas has the same quality standards as conventional natural gas and can therefore replace it. Additional gas is not equivalent to natural gas in terms of composition and can therefore only be partially mixed with normal natural gas. The natural gases available in Germany differ depending on their geographical origin. This means that the required degree of processing of the biomethane also varies regionally.

Quality standards

Natural gas is divided into “natural gas L (low)” and “natural gas H (high)”. Natural gas H has a higher calorific value than natural gas L and is mainly produced in the CIS countries and the North Sea.

Natural gas L contains about 89 percent combustible gases (mainly methane, but also small amounts of ethane, propane, butane and pentane), while natural gas H consists of about 97 percent combustible gases. -

The transport and sale of the fed-in biomethane can be carried out via a biogas or natural gas trading company. The following contracts must be concluded for this:

Biogas balancing group contract

In order to transport the fed-in biomethane in the gas network, the trading company (the transport customer) must conclude a balancing group contract with the balancing group network operator. The network operator balances the quantities fed in and fed out in a balancing group and settles any excess or shortfall with the transport customer.Feed-in contract

In order to regulate the allocation of the fed-in quantities to a balancing group, the feed-in party concludes a feed-in contract with the feed-in network operator. The feed-in contract regulates the quality requirements of the fed-in gas.Exit contract

The end consumer concludes an exit contract with the exit network operator for the withdrawal of gas at the physical exit point. The costs of using the network do not differ from those of transporting natural gas and are paid by the end consumer with the network usage fees up to the virtual point, regardless of the location of the feed-in.Biomethane trading differs from traditional natural gas trading in terms of the proof of origin. The quantities of biomethane fed into the natural gas network must be documented with the corresponding legally required properties (e.g. "produced from renewable resources") from production to use. These are properties that essentially arise from the legal framework.

In addition to handling transport and billing, the trader maintains a gas portfolio. He purchases biogas quantities from various producers and can deliver them to various buyers and end users. In addition, the trader is able to offer deliveries in a structured manner as a band, profile or even a one-off spot delivery. These classic structures are also accompanied by qualitative structures in the biomethane market: the characteristics of origin result in a large number of possible biomethane products. By structuring these features, the dealer can meet individual requirements that arise from the customer's desired utilization paths.

The quantity certificates created are the basis for biomethane customers to prove, for example, compensation claims under the EEG or eligibility under the EEWärmeG.

The German Biogas Register has been available since the beginning of 2011 to standardize this proof of origin and properties. Producers, traders and consumers of biomethane can use the system to document the quantities they feed in. The catalog of criteria used in this process means that all utilization paths remain open to producers and traders. After the information on production conditions has been confirmed by independent experts, the quantities can be assigned to a consumption and thus the proof can be provided without gaps between feed-in and withdrawal. Multiple marketing is thus excluded.

-

Biomethane can be used in various areas due to its properties similar to natural gas:

- Heat: Biomethane can be used in heating systems to heat buildings or generate hot water. In existing gas heating systems, it can completely replace fossil natural gas.

- Fuel: Processed as CNG (compressed natural gas), biomethane serves as an environmentally friendly fuel for vehicles. It reduces CO₂ emissions compared to conventional fossil fuels.

- Electricity: In combined heat and power plants, biomethane is used to generate electricity, often coupled with heat generation (combined heat and power). This enables efficient energy utilization.